Whether a vehicle uses torsion, coil, or leaf springs, it should compensate for bumps and portholes on the road. Additionally, the spring should support the weight without incurring sagging while ensuring the suspension system maintains at a particular height.

These three functions of the spring are essential to the overall comfort of passengers, precise handling of the vehicle, and car lowering configuration. As you can appreciate, these are some of the most crucial aspects that any customer considers while purchasing a vehicle.

Leaf Spring

The Steal multi-leaf springs system is one of the oldest (and most popular) spring designs used in suspension systems. This spring system has numerous benefits for vehicle design and function. For instance, the system not only acts as a spring but also attaches the axle directly to the vehicle’s chassis.

The “mono-leaf” spring meets the application’s needs in some vehicles. While the leaf spring is predominantly used in trucks with solid drive axles, performance road vehicles can also use leaf springs. In such cases, a transverse leaf spring attaches to the independently suspended rear axle, forming a lightweight rear suspension system.

You can also adjust the performance of the leaf spring based on different rid control and load-bearing requirements. You can alter the performance of the spring system by changing the width, thickness, number, and length of spring leaves.

Leaf springs also act as rebound dampeners. The friction between the leaves rubbing together dampens the motion induced by bumps and portholes. In many applications, a plastic unit can replace one of the conventional steel springs to reduce unsprung weight and provide corrosion resistance.

Torsion Springs

Torsion bar suspension systems have been a mainstay suspension system in vehicles that use short-long-arm suspension systems. These systems use a torsion bar as a simple rebound bar, typically four feet long. The bar is designed to twist when put under the load of the suspension system. Given that the torsion bar generally is preloaded with a clockwise or counterclockwise twist, the torsion bar can only fit in a particular side it was designed for use – either left or right.

Some of the notable advantages of torsion bars include compactness and lightweight design. Given that the tension of the torsion bar is controlled using a threaded screw adjustment, the torsion bars allow users to control the suspension height precisely. Additionally, torsion bars can be installed on either the lower or upper control arm, making for a versatile suspension system.

Coil Spring

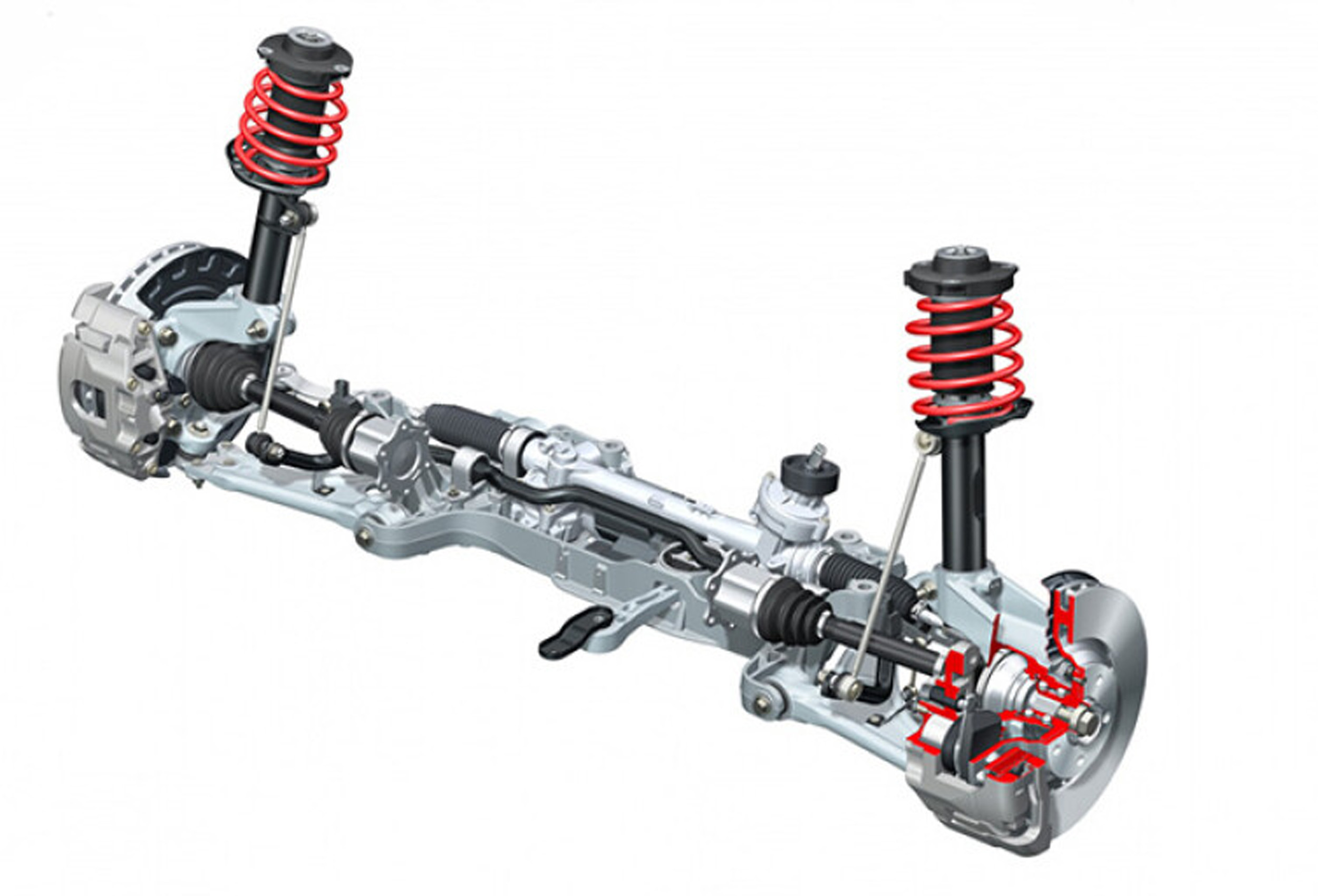

To better understand how a coil spring functions, think of it as an extended, thin torsion bar that’s wound into the shape of a choil. The coiled wire twists during the spring’s extension and compression cycles, thereby operating on similar principles as torsion bars.

Its main advantage is the compactness of the design and the space economy it offers. It has been used in various suspension designs such as the MacPherson strut, independently sprung rear axle, solid axle with trailing arms, and SLA suspension systems that use coil-overs or shock absorber configurations.

The vast majority of modern imports use coil springs that use the MacPherson strut design. Typically, the wire gauge, overall diameter, length, and the number of coils will determine the coil spring and general suspension characteristics.

Some coil springs are designed as variable rate springs. This means that their load-bearing capacity increases as it’s compressed. Variable-rate coil springs are typically used in vehicles intended to haul a heavy load.

How Springs Work

Springs use the sprung-to-unsprung weight/force ratios to provide cushioning. A wagon with no spring will have a 100% unsprung weight. In this example, when the coils are placed between the axles and chassis, its sprung-to-unsprung forces/weight ratio might end up being 10% representing the wheel and axle weight, and 90% for the chassis weight.

When the wagon starts to move, the spring absorbs the impact of road irregularities.